Page 52 - Danish Offshore Industry 2020

P. 52

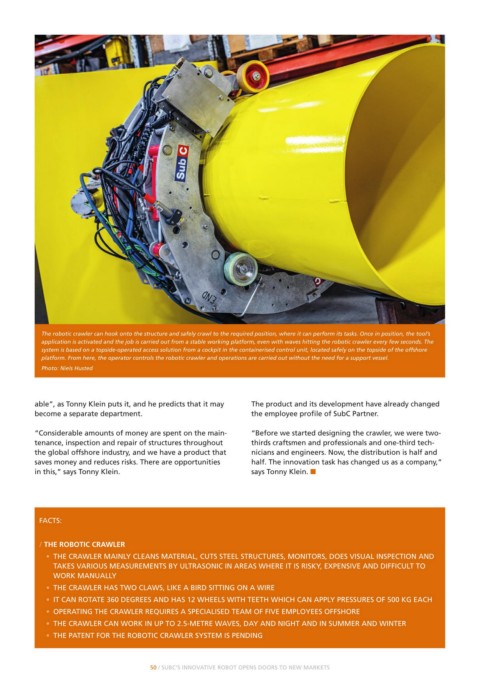

The robotic crawler can hook onto the structure and safely crawl to the required position, where it can perform its tasks. Once in position, the tool’s

application is activated and the job is carried out from a stable working platform, even with waves hitting the robotic crawler every few seconds. The

system is based on a topside-operated access solution from a cockpit in the containerised control unit, located safely on the topside of the offshore

platform. From here, the operator controls the robotic crawler and operations are carried out without the need for a support vessel.

Photo: Niels Husted

able”, as Tonny Klein puts it, and he predicts that it may The product and its development have already changed

become a separate department. the employee profile of SubC Partner.

“Considerable amounts of money are spent on the main- “Before we started designing the crawler, we were two-

tenance, inspection and repair of structures throughout thirds craftsmen and professionals and one-third tech-

the global offshore industry, and we have a product that nicians and engineers. Now, the distribution is half and

saves money and reduces risks. There are opportunities half. The innovation task has changed us as a company,” More than 45 years

in this,” says Tonny Klein. says Tonny Klein. n

in Offshore Asset Integrity -

Experience makes a world of

FACTS: difference FORCE Technology -

Safe steel structures

/ THE ROBOTIC CRAWLER

• THE CRAWLER MAINLY CLEANS MATERIAL, CUTS STEEL STRUCTURES, MONITORS, DOES VISUAL INSPECTION AND

TAKES VARIOUS MEASUREMENTS BY ULTRASONIC IN AREAS WHERE IT IS RISKY, EXPENSIVE AND DIFFICULT TO

WORK MANUALLY

• THE CRAWLER HAS TWO CLAWS, LIKE A BIRD SITTING ON A WIRE

• IT CAN ROTATE 360 DEGREES AND HAS 12 WHEELS WITH TEETH WHICH CAN APPLY PRESSURES OF 500 KG EACH

• OPERATING THE CRAWLER REQUIRES A SPECIALISED TEAM OF FIVE EMPLOYEES OFFSHORE

• THE CRAWLER CAN WORK IN UP TO 2.5-METRE WAVES, DAY AND NIGHT AND IN SUMMER AND WINTER

• THE PATENT FOR THE ROBOTIC CRAWLER SYSTEM IS PENDING

forcetechnology.com

50 / SUBC’S INNOVATIVE ROBOT OPENS DOORS TO NEW MARKETS